CHICKEN RAISING TECHNIQUES

Preparatory steps in the broiler raising process

Preparatory steps in the broiler raising process- Workers prepare the coop to receive the chicks

- Check the nursery equipment, heater, coop and hygiene monitoring sheet

- Prepare feeding trays and water troughs containing electrolytes and vitamins → Clean the water troughs daily

- Turn on the heater 15 minutes in advance and assess the temperature

Receiving chicks in the broiler raising process

Receiving chicks in the broiler raising process- Handle the receipt of chicks from the chicken carrier with care

- Check stock the delivery note, shipping information, and chick coop

- Check the correct quantity, farm address, and farm name in the quarantine certificate to complete the procedures for exporting chickens later

- Release and count the chicks, and record the numbers of weak, dead, failed chicks

Taking care of broilers in the broiler production process

Taking care of broilers in the broiler production process¤ Nursery stage (14-20 days)

¤ Growing stage

1. Feeding the broilers

- Workers feed broilers at 7:30 am every day according to the prescribed feeding schedule

- Ensure the number of feeding trays and water troughs, water speed, height of water troughs and feeding time according to the given regulations

- Workers record and report the feed and water intake of broilers

2. Providing broilers with water

- Techniques for mixing medicine, vitamins, and minerals for broilers

- Type of medicine and medication schedule according to the procedure

- Record the number of medicines and vaccines used after each application

- Clean drinking troughs at 9am and 3pm every day

3. Checking the health of chicks

- Check the feed and water intake of the chicks

- Check for Aspergillosis in the chicks

- Check the status, flexibility, and movement of the chicks

4. Conducting vaccination

- Make vaccines according to the procedures and instructions from the farm management and technicians

- Conduct the recording and reporting after vaccination

5. Counting the broilers

- Count the number of broilers during each vaccination

- Adjust broiler density if required by the specifications

- Workers record the number of dead/rejected broilers daily and report to the management

6. Monitoring the broilers’ weights

- Weigh the broilers and record the broilers’ weights

- Record the amount of feed and the broilers’ weights, and make reasonable adjustments

7. Monitoring the microclimate of the coop

- Monitor and record wind speed by the broilers’ age weekly

- Monitor temperature according to specifications

- When the chicks are from 1 – 7 days old, workers record the temperature in the coop in the temperature report; afterward, monitor the temperature via viber

- Monitor lighting schedule and intensity according to the specified specifications

8. Laboratory tests

- Collect the broilers’ blood to check for antibodies/antigens

- Collect the broilers’ blood/stool/tissue/swab/coop lining samples to check whether there is any disease

- Collect water samples for testing (2 times/year)

9. Treatment of diseases

- Techniques, doctors, and the use of medicines as prescribed

- Periodical surgery examination to control diseases if possible

10. Cleaning

- Workers clean and tidy up the chicken coop

- Clean boots after work

The feeds for broilers shall be changed according to each stage; after within 20 days from the application of antibiotics, the use of antibiotics will be restricted or not allowed to avoid antibiotic residues on broilers when sold.

CJ's technical process in raising breeding chickens

CJ's technical process in raising breeding chickens- Newly imported chicks must be immediately transferred to the nursery coop with gentle and careful handling.

- Feed the chicks with feeds, water mixed with electrolyte solution (acid 4way), vitamins (permasol, AD3E, etc.), and antibiotics (ENRO, PULMOTIL, etc.) depending on the status and health of the chicks.

- Nursery time: 14-21 days depending on the health of the chicks and the current weather.

- Nursery temperature: maintain 34- 35 0C on the first day, then gradually decrease 0.5 0C per day until it reaches 30- 310 C.

⇒ Note: the reduction of nursery temperature must be based on observations of the chicks’ health and the weather during the nursery. It is required to regularly monitor the coop temperature with a thermometer or by observing whether the chicks gather due to lack of heat or spread out to breathe due to excessive heat.

All works from preparing the coop, feeding, providing water, vaccination, monitoring broilers’ health are done methodically and scientifically by CJ farm staff. From the time the breeding chickens start laying eggs to the time the eggs are brought to a hatchery, processes of monitoring and selecting are done carefully and thoroughly to meet prescribed standards such as: the weight of an egg must be 50 grams or more; the eggs must be clean, intact, not cracked, broken, distorted, deformed, and have the standard color of the breed. Besides, the successful application of the multi-stage incubation technique gives a high hatch rate and outstanding quality. Some of the chicks after hatching are distributed directly to the suppliers, and the rest are transferred to broiler farms.

Lighting schedule for breeding gilts

Lighting schedule for breeding gilts

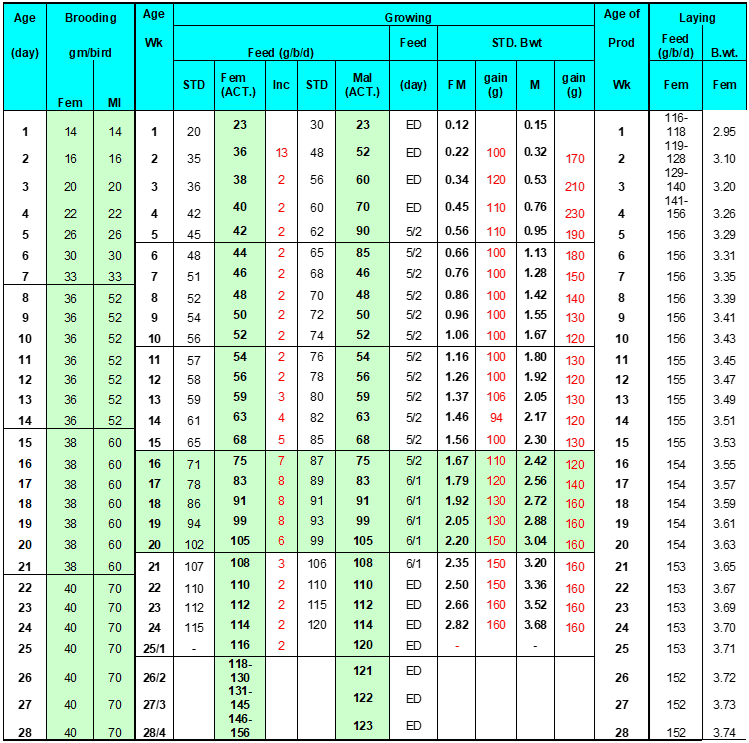

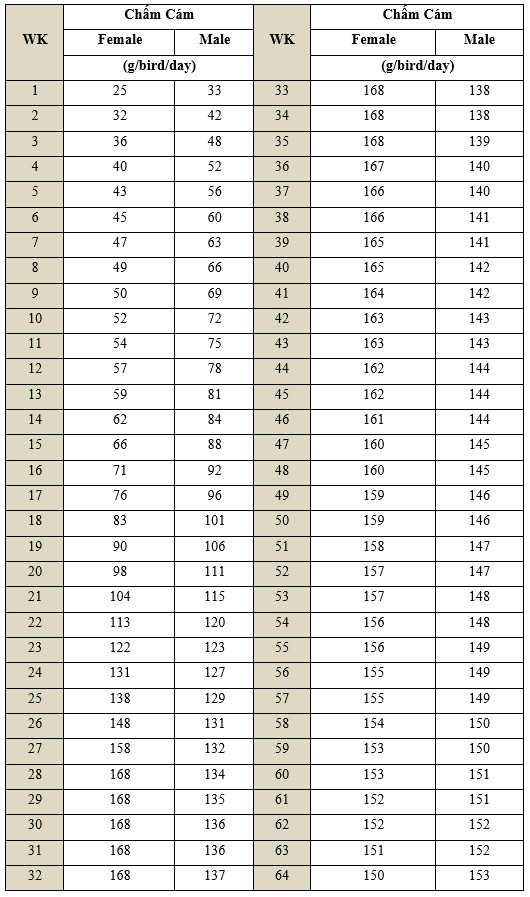

The feeding process based on the process of increasing feed according to the age of the breeding chickens

The feeding process based on the process of increasing feed according to the age of the breeding chickens

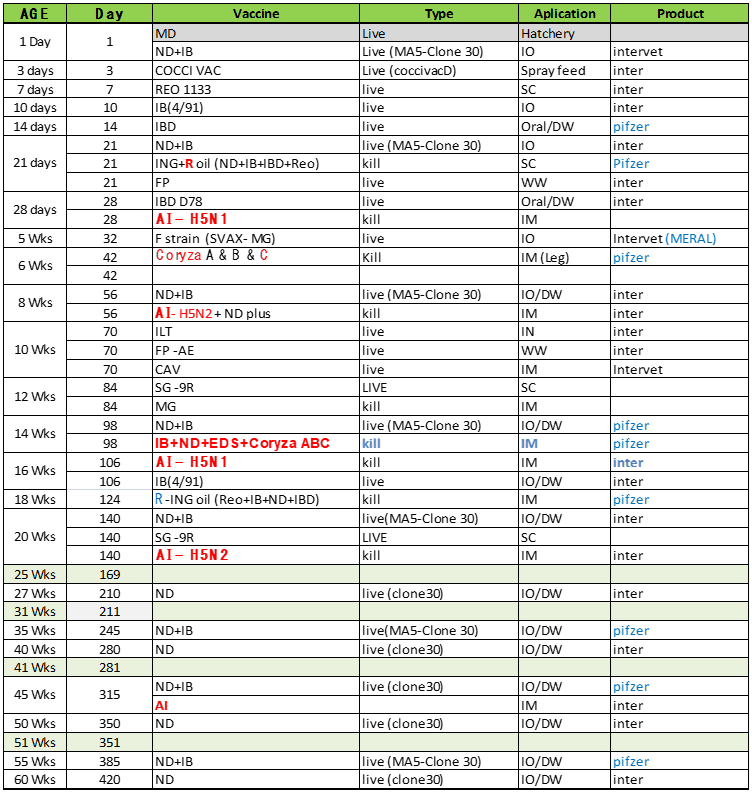

Vaccination procedure for breeding chickens

Vaccination procedure for breeding chickens

Table of standards for monitoring the standard weight of breeding chickens

Table of standards for monitoring the standard weight of breeding chickens